Here we list the top reasons why you should buy or specify Timberlink Tasmanian plantation pine in your next building project.

1. Tasmanian Pine Plantations are helping to mitigate climate change by removing CO2 from our atmosphere

The increasing amount of carbon dioxide in our atmosphere is warming the planet. Trees absorb CO2 as their food, which they then store as carbon. This carbon remains locked in the timber for its lifetime even when harvested and manufactured into products. Indeed, around 50% of timber’s weight is stored carbon. This makes all timber products carbon storage devices.

If all trees do this, what makes Tasmanian Pine Plantations so special?

Growing young trees absorb CO2 at a quicker rate than older trees and a plantation’s replant-harvest cycle means there is always a high proportion of growing trees in the ground. By harvesting mature trees and replacing them with seedlings, plantations are playing a key part in helping to offset carbon dioxide emissions and other greenhouse gases that would otherwise contribute to climate change.

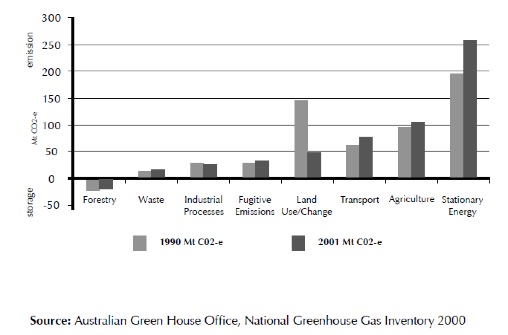

Forestry is the only Australian industry that absorbs more greenhouse gases than it releases. In 2001, Australia’s plantations and managed forests stored a net 22.7 million tonnes of carbon dioxide. No other industry sector acts as a positive carbon sink.

2. Less energy is used producing Tasmanian Plantation Pine than any other building products

Timber is strong, natural and renewable. Making it into fit-for-purpose building products, requires low energy giving timber the lowest embodied energy of any major building material.

While the amount of energy embodied in a home obviously varies with its design and location, roughly speaking:

- a steel beam requires more than 10 times the production energy of the equivalent timber beam;

- aluminium window frames use over 50 times the energy of equivalent timber frames;

- on a weight-for-weight basis, the manufacture of steel consumes 300% and aluminium 1500% more energy than its timber equivalent; and

- brick cladding uses significantly more energy than timber cladding;

(Source: Ferguson, 1996 ‘Environmental Properties of Timber)

By choosing Tasmanian Plantation Pine products over these more fossil-fuel intensive construction materials you can significantly reduce your home’s environmental footprint (Petersen and Solberg, 2002).

3. Making Tasmanian Plantation Pine products we try to get the most out of every log

Sawmilling is not only low energy. At Timberlink, we use the latest technology to scan every log that comes into our Bell Bay mill to make sure we get as many quality pieces of timber out of each log as possible.

Any part of the log that we can’t cut into a solid timber product, is either cut into high quality woodchip to be used to make particle board, cardboard or paper or we use it to power our drying kilns. Even the bark is used by landscaping supply companies to make gardening products. In comparison, most of the energy used in the extraction and processing of other building materials is non-renewable fossil fuels.

So, for your next building job, make sure you choose Timberlink Tasmanian plantation pine. Your purchase is supporting a locally grown and made renewable building product.